Extrusion Die Technology

Global Die & Extrusion Technology Inc. delivers exclusive die technology for mono or co-extrusion systems as a complete package or in components to customer's specifications in order to produce the best quality films. Each die and individual spiral mandrels are design with a great consideration of individual material viscosity. Both mono and co-extrusion die spirals are designed by proven custom in house developed computer simulation software using the rheology of the resins. Consequently providing optimum output with reasonable flow back pressure. To guarantee the best design for each individual application Global works directly with the customer, analyze proposed resins, layer configurations and provides maximum versatility.

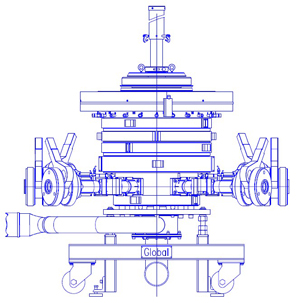

The Global co-extrusion die is the most advanced and versatile blown film co-extrusion dies in the market designed with optimized performance. Precise manufacturing tolerances, design accuracy and a superior final product are assured by direct data interface between the CNC machines and design software. Its performance is further enhanced by its lowest wetted surface area, resulting in very short residence time, low pressure drop, and no resin hang up for easy purging. Global dies are available from 1 to 9 layers to suit customer's requirements.

Features:

- Dies are manufactured from high grade alloy steel (4140 or 4340) which is heat treated and stress relieved prior to final machining.

- High output per circumferential inch of die lips.

- Special technique is used in the co-extrusion die to avoid inter-layer instability.

- Design provides the lowest surface area, very low residence time and pressure drop resulting no polymer degradation and guarantees high output.

- Stacked co-extrusion die with choice of conical mandrels.

- Choice of extruders having the same centerline height.

- Manufactured in state-of-art CNC machinery for the best possible accuracy.

- Designed to extrude a wide variety of polymers in multilayer structure.

- Resins - PE, PP, PA, EVOH, PVC, PS, PU, HDPE, PVdC, Barex and Tie resins.

- Optional Auto-gauge control system for optimum gauge control.

Gobal's dies are provided with exclusive PRO/Process Simulation Software which predicts problems and offer solutions in order to perfect the required structure.

Services

- Extrusion Die Technology

- Retrofit Blown/Cast Film Equipment

- Consultancy & Technology Development

- PVC Cling Film Technology

- Cast Film Line for Colostomy Bags

- Pro/Process Simulation Software

- Pro/Flow Die Design Simulation Software